Lime kiln designs

Practical Action

kiln, and the kiln is charged through a gate on the housing, by means of a bridge (5).

Limestone is supplied by a road vehicle from the quarry. The kiln draught is produced by a

chimney (4), 10 metres high and 0.6 metre diameter, located at the top of the housing. The

burners (6) are located 4 metres up the kiln, making the heights of the zones 5.5 metres

preheating, 2.5 metres burning, and 4 metres cooling.

There are four burners (6), two at each side, which are somewhat displaced out of directly

opposite alignment. Other features of note are the burner inspection platform (7), and the

four kiln discharge channels (8).

16 Ton per Day Kiln

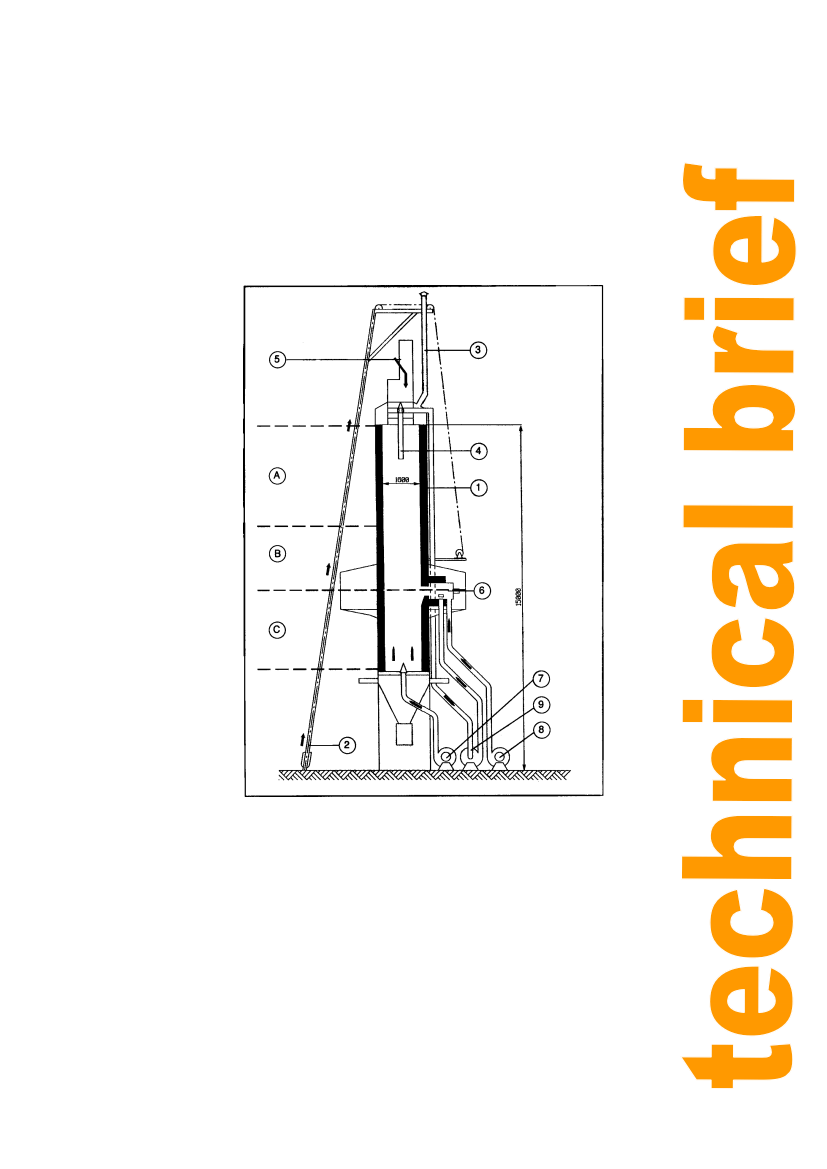

(Figure 3)

The shell of this kiln is

cylindrical and made out of

sheet metal (1). An

electricity supply is

required for this kiln to

operate a forced draught

system; hence it is really a

low production, and not a

low cost kiln.

Limestone is loaded by a

pulley-operated skip hoist

(2), and the rate of charging

of stone into the kiln is

controlled by a load cell.

Discharge is by a special

gate (5), which can be

sealed against air leakage

when closed so the kiln can

be left open at the top.

Flue gas is discharged by a

chimney (3). Another

feature of this kiln is a pipe

(4) to recycle some of the

flue gas into one of three

combustion chambers (6).

The lengths of the

preheating, burning and

cooling zones are 5.5,2.5

and 4.0 metres

respectively.

Figure 3: 16 ton per day kiln.

The combustion chambers (6) are fed with fuel oil, air and recycled flue gas. The fuel oil is

gasified by the heat in the combustion chambers without the need form atomisation with

steam. A fan (8) supplies air to the combustion chamber, another fan (9) recycles flue gas to

the combustion chamber, while a third fan (7) feeds cooling air into the kiln. By controlling

the relative amounts of cooling air and recycled flue gas entering the kiln, good control over

temperature in the kiln can be obtained.

This type of kiln is very efficient in terms of its energy usage, consuming only 1100 kcal per

kilo of quicklime.

4